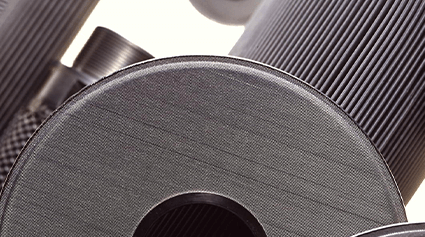

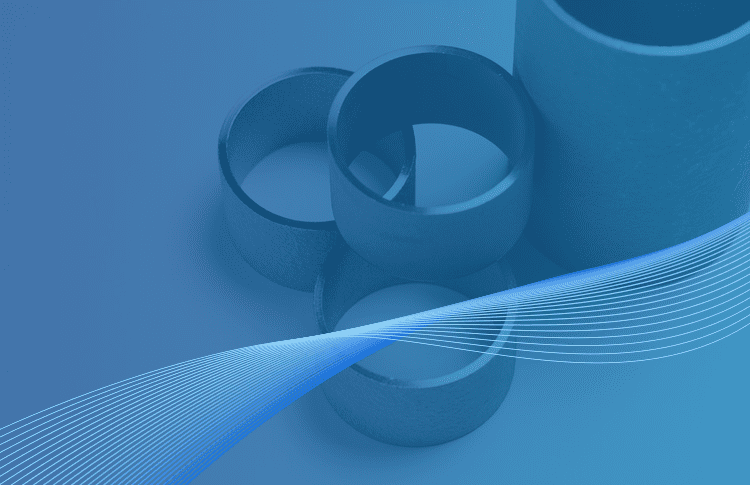

We offer the cleaning options most suitable for the elements and filters.

As all of our cleaning equipment is located inside the filter element manufacturing plant, we can maintain a consistent quality control throughout the cleaning process until final inspection.

This in-house facility also enables us to respond quickly to any emergency request.

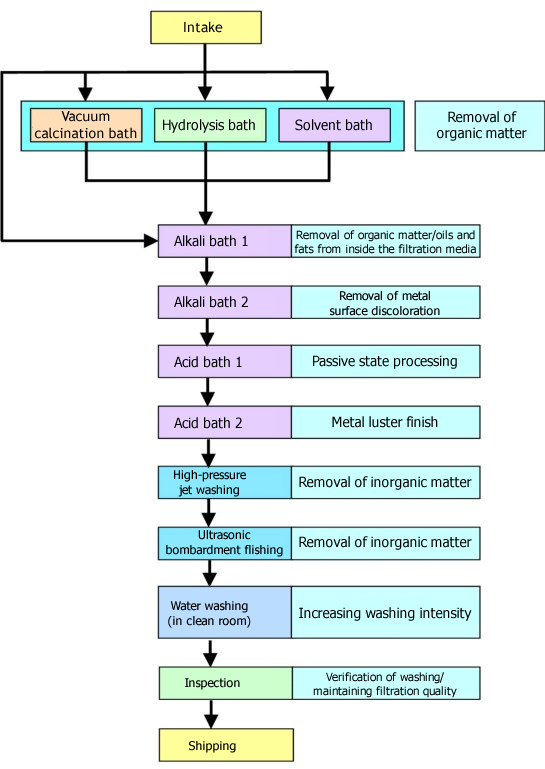

Cleaning process consists of :

① Cleaning/recycling

We recommend the most suitable cleaning method from 5 options depending on the condition of the residue and the contaminants.

1 ) Baking furnace for cleaning

2 ) Hydrolysis regeneration cleaning system (by HYPOX)

3 ) Chemical cleaning (Acid/Alkali bath)

4 ) Hot water high-pressure jet cleaner

5 ) Ultrasonic bombardment flishing

② Inspection after cleaning

* Bubble point test

The cleaned element is placed 50mm below the surface of IPA (isopropyl alcohol) for the bubble point test and the element is filled with air with gradually increased pressure. Air pressure measured at the initial bubble point and at the burst bubble point (bubbles emerging from all over the element) will indicate any wear or damage to the element.

* Air flow test

Pressure drop is measured after a certain volume of air fills the element; this confirms whether the element was sufficiently cleaned or not.

③Quality control of elements

We discuss with clients to determine the combined requirements of the initial bubble point and burst bubble point figures and the air flow test to ensure we prepare our inspection report to meet your quality control requirements.

④Simultaneous cleaning of the housing