OUR VALUE

Our Value

OUR VALUE

Total engineering company

- From outer space to the ocean floor, we propose the best solution to various fields -

As a total filter engineering company, Fuji Filter develops, designs, manufactures and sells high-precision industrial filters and filtering systems.

Filters are indispensable in manufacturing. Established in 1966, we have been thoroughly addressing questions such as "Why are filters required?" and "What is the best solution for the customer?" and improving the quality of products.

NEVER SAY NO -

Consider all possible ways to make it real.

We maintain a “NEVER SAY NO” spirit and try to open further possibilities related to filters. We have bravely faced unknown fields and serious challenges and have always tried to provide "the best solution for the customer."

Filters, the core of our business, will remain indispensable in many industries for years to come. We will continue to play a behind-the-scenes role in various industries worldwide, while always maintaining our curiosity and valuing the ideas we have gained through our business.

We have customers in 55 countries/regions.

We have actively expanded our business across borders since our founding in 1966, when our first overseas branch was established. We deal directly with our customers without using intermediaries such as trading houses or agencies. Currently, we have business relationships with more than 1,000 companies in 55 countries and regions around the world.

Business practices, trends, culture, and people’s values differ in each country and region. We will continue to contribute to the development of the industrial world by leveraging our strength of significant knowledge gained from doing business in many countries and regions.

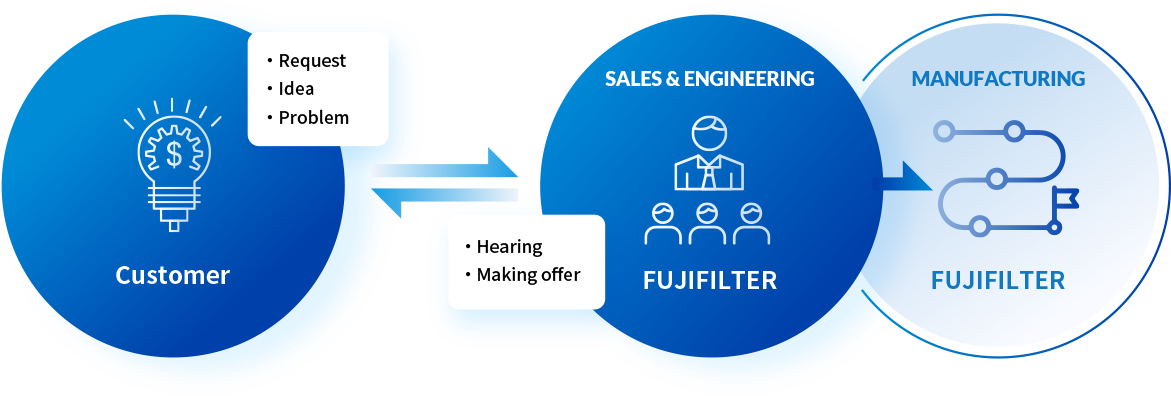

We provide total service related to filters, from planning and design to production and sales.

As a total filter engineering company, we offer total service, from planning and design to production and sales. We propose the best solutions.

If you have a manufacturing project to complete or questions about product development, production methods, or other manufacturing issues, please feel free to contact us.

We cover vast fields, ranging from outer space to the ocean floor.

Our products are used in a wide range of industries and applications, including the chemical, food, pharmaceutical, automotive, aerospace, appliance, and information technology industries. In recent years, our technological capabilities have also attracted attention in the renewable energy transition and other global environmental initiatives.

We are not just a filter manufacturer. We leverage the knowledge and experience we have gained through our business in a wide range of fields to meet diverse needs and challenges as a product development partner.

Oil & Gas and Petrochemicals

Filtration for OIL&Gas process/Filtration for gas process

Clean Energy

Sustainable Aviation Fuel/Hydrogen/Ammonia/Biomass power generation/Chemical recycling

Chemicals and Polymers

Polymerization ・ Granulation / Compounds / Films and Sheets / Optical Lenses / Battery Separators / All Solid State Battery Materials

Aerospace and Defense

Oil water separation of aviation fuel/Aviation fuel/Parts for Rocket/Heat exchanger parts for external combustion engines

Ships

Marine fuel/Ballast water/LNG・LPG・Ammonia・Hydrogen gas/collection of ocean plastic waste

Automotive

Electric Vehicle/ Fuel Cell Vehicle/Fuel injectors/Airbag

Machine Tools and Construction Machinery

Hydraulic equipment/Pneumatic components/Oil mist separator for vacuum pumps /Breather/Removal for solid in various machine

Pharmaceuticals & Biotechnology / Medical Devices

Raw material of hollow fiber membrane for artificial dialysis/Orthodontic materials/Parts for heart-lung machine/Parts for medical equipment

Food & Beverage

Soft drinks/Alcoholic drinks/Milk beverage/Cooking oil

Semiconductor and Electrical Equipment

Gas filters for semiconductor manufacturing equipment / Parts for semiconductor assembly process / Parts for heat exchangers

Water Treatment

Wastewater treatment/Cooling water/Seawater treatment

Other Industries

We supply our porous body to various industries.