PRODUCT

Product

PRODUCT

Porous Media

Porous Media All

Resin Paper

Sintered Powder

Sintered Winding

Filter Element

Filter Element All

Filter System Unit

Filter System Unit All

Gas

Pressure Vessel General Filter

Liquid

Automatic Cleaning Filter System

Centrifugation

Coalescer

Ultrafiltration

Polymer

Parts

Parts All

Adsorption Parts

Car Parts

Foaming Material Sparger

Heat Exchanger

Hydraulic Equipment

Medical Device

Powder Transfer Parts

Sound Deadening Absorbing Material

Reset Refinement

Filter Element/Porous Media

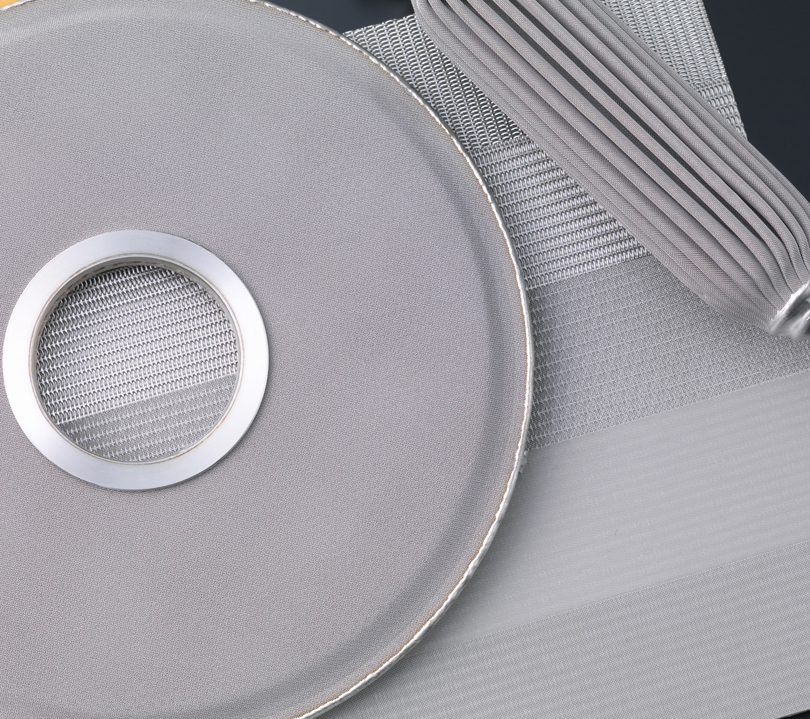

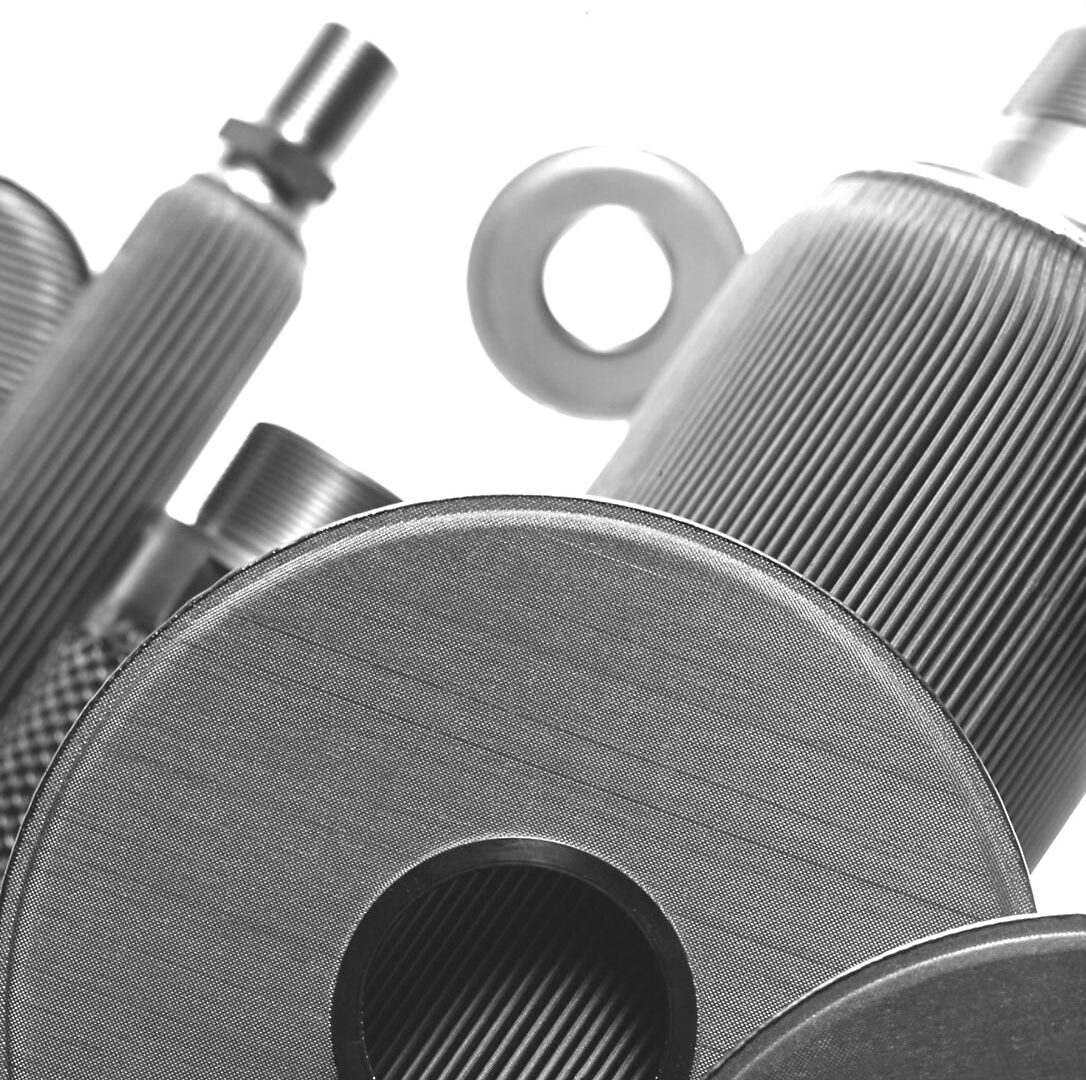

《FUJIPLATE》Sintered metal mesh element

Fujiplate filter elements are ideal surface filtration type filter elements made by laminating and sintering together wire mesh of various alloys including stainless steel. The fine mesh with precisely controlled pore size is combined with protective and reinforcing layers according to the application. Fujiplate filter elements have excellent durability and corrosion resistance, and are used ...

Filter Element/Porous Media

《FUJIFLO》Sintered metal mesh element

FUJIFLO elements are made of uniformly distributed porous metal plate with a degree of accuracy in the micron range. The precision steel mesh is laminated and sintered to form a multilayer plate and then press-rolled to obtain accurate control of air flow properties and give a smooth finish to the surface. FUJIFLO offers outstanding durability ...

Filter Element/Porous Media

《FUJI METAL FIBER》Sintered metal non woven fabric

FUJI METAL FIBER is a non-woven filter made of laminated, sintered layers of metal fiber felt (stainless steel is standard). This medium has excellent heat, pressure and corrosion resistance, and it is used for high temperature, high viscosity fluid filtration. It has a typical deep filtration structure giving high filtration efficiency, low filtration resistance, and ...

Filter Element/Porous Media

《FUJIMICROY》Sintered metal non woven fabric

A porous tube made using wires of small diameter. Features Functions that can be added Application examples Specifications Materials SUS316, SUS316L, SUS304, SUS347, etc Sizes ID : φ3.5-20 mm, OD: φ5-22 mmThickness : 0.75-1.00 mmLength : 20-200 mm * Samples are available. Custom materials, inner/outer diameters, lengths and pore sizes are possible.

Filter Element/Porous Media

《FUJI METAL BALM》Sintered metal non woven fabric

FUJI METAL BALM is our heat exchanger filter element with over 90% porosity ratio. It is used as the regnerators of the solar thermal Stirling engines for power generation.

Filter Element/Porous Media

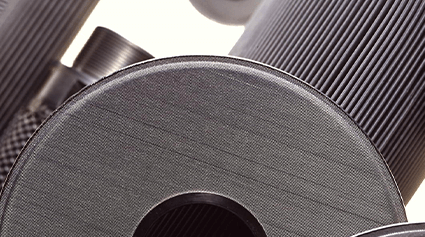

《FUJILOY》Sintered seamless filter

A sintered seamless filter made by winding a single stainless. Features Functions that can be added Application examples Specifications Materials SUS316, SUS316L, SUS304, SUS347, etc Sizes ID: φ1.0 mm or larger, OD: φ1.3-80 mm, Length: 3-150 mm, Pore size: 2-500 um* Sample are available. Custom materials, inner/outer diameters, lengths and pore sizes are possible.

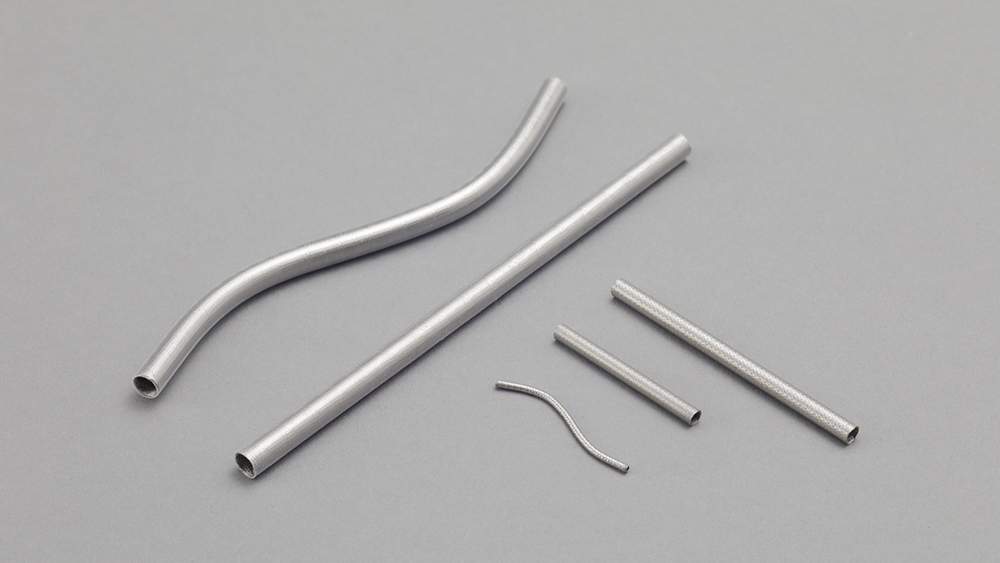

Porous Media

《FUJIFRAPE》Seamless porous tube

A seamless porous tube that can be bent flexibly with fingers. Features Functions that can be added Application examples Specifications Materials SUS304, SUS316, SUS316L, SUS347, etc Sizes ID: φ2 mm, 3 mm, etc. Pore size: 2-500 um* Samples are available. Sizes other than indicated above are also possible upon request. How much N is necessary ...

Porous Media

《FUJIBEYOND》Seamless porous tube

A stretchable seamless tube. Features Functions that can be added Application examples Specifications Materials SUS316L and Ti Sizes OD: φ6, Length of base material: 50-200 mm, Thickness: 1.15 mm OD φ2.9, Length of base material: 50-200 mm, Thickness: 0.3 mm *Samples are available. Custom materials, inner/outer diameters, lengths and pore diameters are possible. How much ...

Porous Media

《FUJI MULTI CLAMP》Non sintered metal mesh

Clamp mesh is more durable against degradation/deformation thanks to its wavy structure and is even more robust because it is made with larger wire. After being pressed against the toothed gear, the wire material forms a wavy shape and is woven into a mesh so that wires at crossing points run at the right angle.

Filter Element

《FUJIBON》Pleated paper wound filter

FUJIBON filter elements are made of helically wound cellulose ribbon impregnated with phenolic resin and are highly corrosion resistant. The elements are heat cured and fused. Filtration takes place as the filtrate flows through the innumerable minute gaps formed between the layers of ribbon. This is one of the strongest paper filters available, it is ...

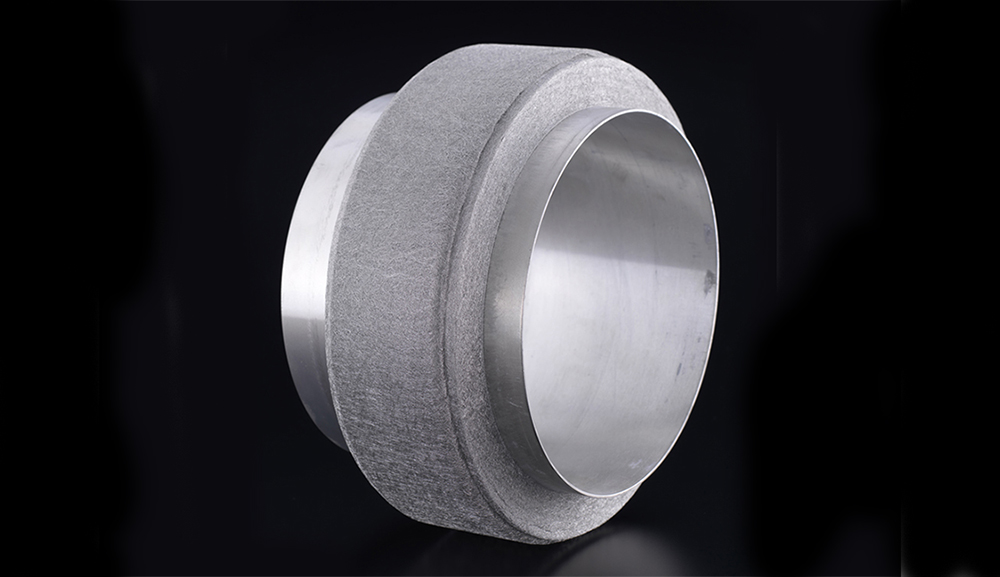

Filter Element/Porous Media

POWDER SINTERING

Powder sintering is a metallurgy process where metal powder mass becomes compact body called ‘sintered’ after being heat treated in the temperature just below its melting point. A similar process is baking (calcination). Standard specification

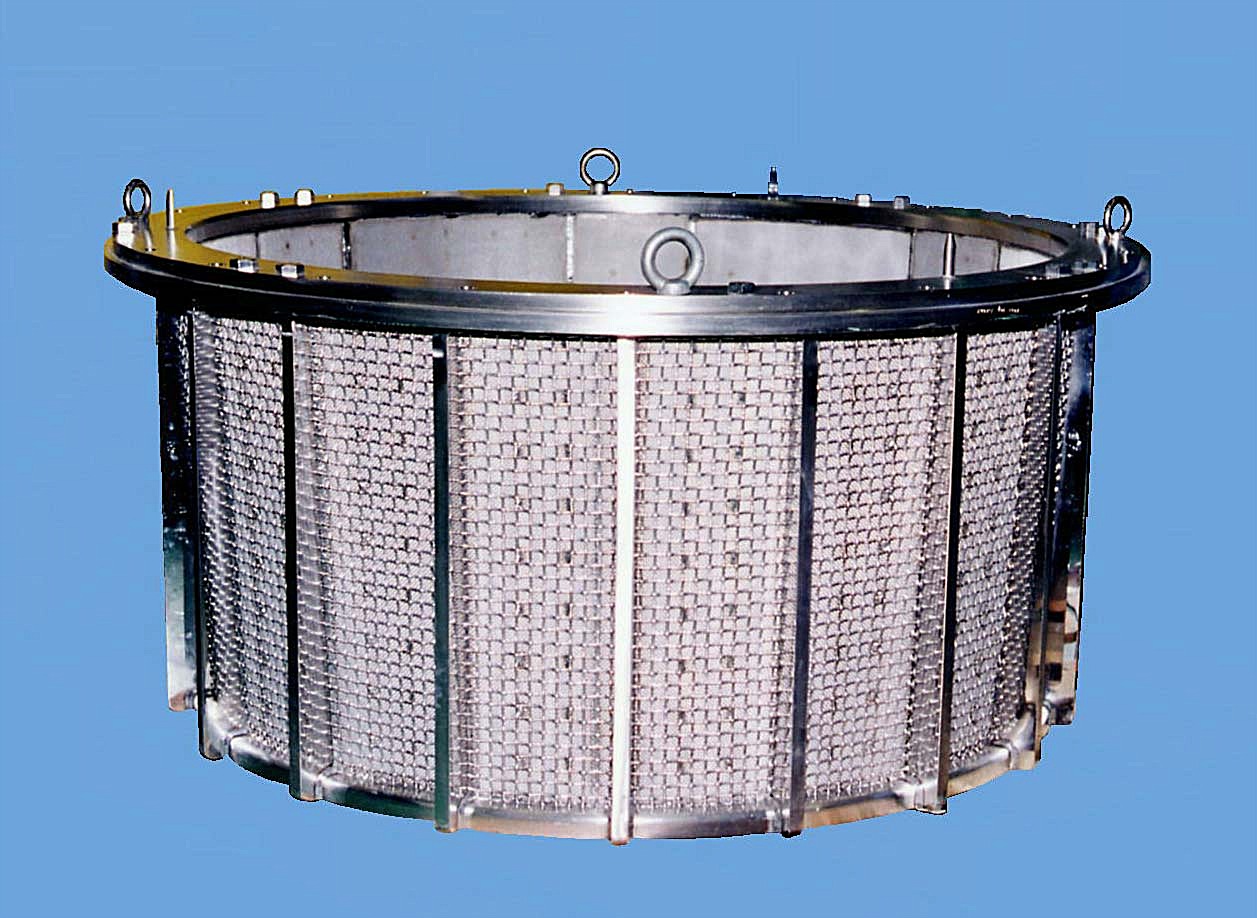

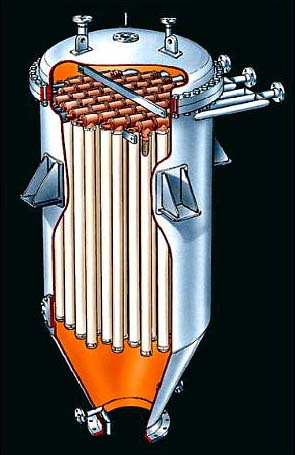

Filter Element

Basket Filters For Centrifuges

Solid constituents contained in process solutions are recovered by centrifuging in such production processes as pharmaceutical products, food and fine ceramics. The use of FUJIPLATE filter elements ensures very accurate filtration in the 2 micron range at high revolution speeds. FUJIPLATE can be easily flushed, permits quick detachment of cake and can be machined into ...

Filter Element

FUJI Filter Separators

FUJI Filter Separators have the function of separating free water contained in aviation fuel, mainly jet fuel, gasoline and kerosene, and they also remove contaminants. These filters are manufactured to API/IP-1581 specifications. They are installed at airports, and loading lines of refinery terminals, both in Japan and throughout the world. The separator contains a coalescer which ...

Filter Element

FUJI Wound Filter

FUJI Wound Filter elements are made of robing yarn and the winding pattern is determined according to the filtration accuracy required.Winding density is greater nearer the center of the element, thus the structural density varies throughout the depth of the element. This is a typical depth filtration type element, and is capable of a very ...

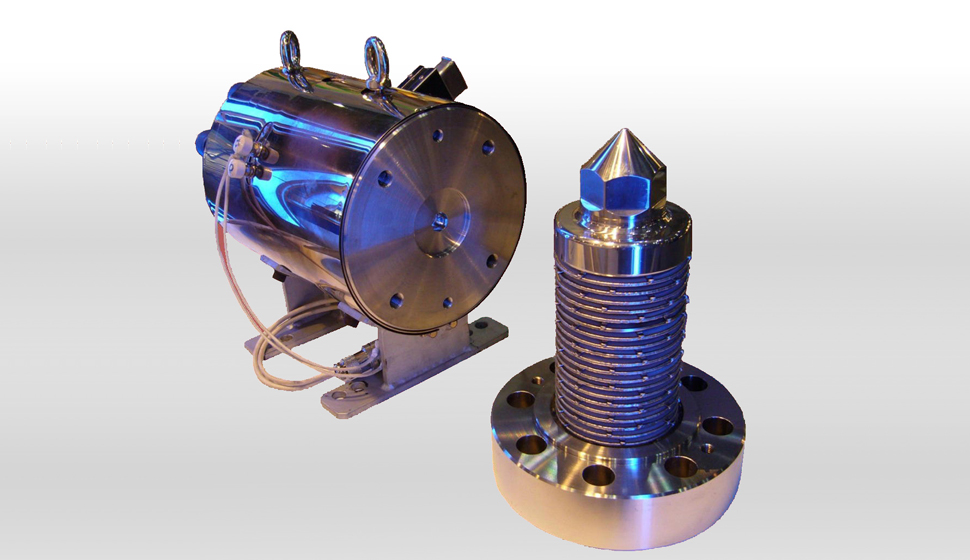

Filter System Unit

Polymer filters (leaf disc type)

Features Fuji leaf disc polymer filters are widely used in polymer pellet manufacturing lines and film forming lines, etc. They have been conventional and well-proven filters available on the market for many years. They are suitable for a long-run operation because they are suitable for a long-run operation as they are capable of filtering large ...

Filter System Unit

Polymer filters (candle type)

Feature Fuji Filter has re-engineered these pleats polymer filters recently and has been successfully selling to the film manufacturing sector, which did not use this type of filters previously. Their simple structure means relatively economical start-up and maintenance cost compared to the leaf disc filters. They are perfect if you are looking for easy-to-handle filters ...

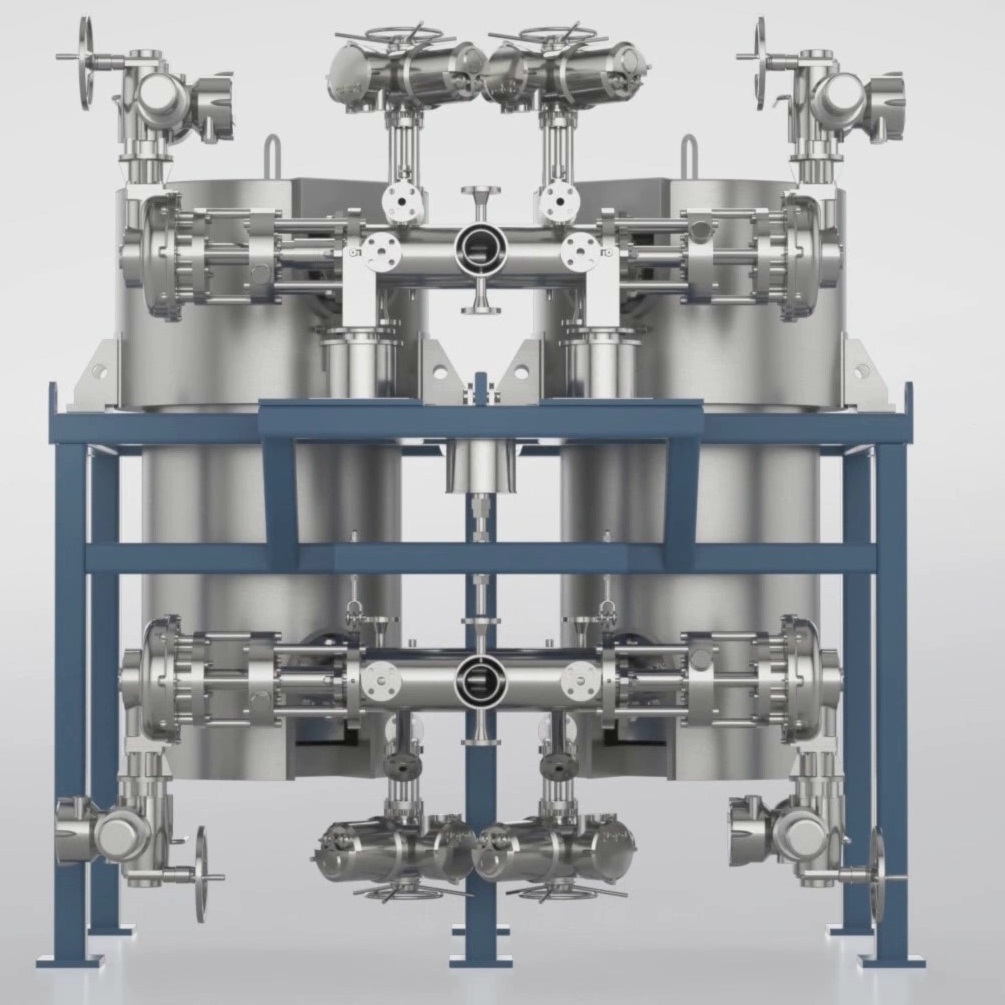

Filter System Unit

FPF polymer filter system

In the same way as the vertical type, the FPF polymer filter system (horizontal) continuously filters polymer for synthetic fiber, film, and plastic products without shutting down the production process and implements filter unit switching. The system uses sintered metal filters with excellent ability to remove solid and gel contaminants. Plug valves are used as ...

Filter System Unit

DPF polymer filter system

Fuji Duplex Polymer Filter System (upright type) is a leading filter system in polymer polymerzation lines using FUJIPLATE (laminated mesh sintered structure) and FUJI METAL FIBER (laminated non-woven metal fiber structure) elements.The A Vessel or B Vessel filter is in constant operation, therefore work does not need to be interrupted. This system and its design ...

Filter System Unit

《Line filters/ Bag filters》Pressure Vessel / Filter

Line Filter System (Fuji Filter Vessel) is a versatile system for a wide range of fluids as it is fitted with an easily attachable/detachable V band which makes it easy to replace elements. As the inlet and outlet ports of the fluids are designed to be located at the same level, it is easy to ...

Filter System Unit

《FUJI JET FILTER》Dock-Dock Maintenance-Free Super Fine Filter for Marine Use

FUJI JET FILTER is an innovative filtration system for marine fuel and lubricants with outstanding filtration capability.Still keeping with the concept of direct cleaning of filtration media by high-pressure jet spray and “Dock- Dock Maintenance Free”, the new FUJI JET FILTER has cut down on installment space, improved operation procedures and optimized devices.FUJI JET FILTER ...

《FUNDABAC》Cleaning type process filters

FUNDABAC automatic backflushing filtration system enables repeated operations of precoat filtration and cake recovery without the need to remove filters after every cycle. It has proven to be successful in the chemical, pharmaceutical, food and environmental facility sectors. Features Application

Filter System Unit

BBW FILTER SYSTEM

Coming Soon …

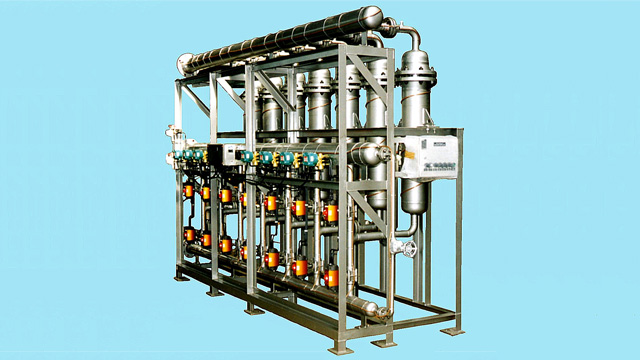

Filter System Unit

《FEED FILTER》FUJI Automatic Backflushing

The various functions of the FUJI Automatic Backflushing Filtration Systems from process fluid, filtration, prepurge and backflushing are controlled by a PLC. It can be programmed to comply with the filtration and washing of the customer’s original system matched to application requirements. It has made possible double backflushing, up until now widely considered to be ...

Filter System Unit

FUJI Oilmist Separator/Air breathers

By fitting a FUJI Oilmist Separator to the exhaust outlet of vacuum pumps such as rotary and reciprocal types, the generation of unpleasant oil mist is curbed, and a pleasant work environment is attained. The FUJI Oilmist Separator has been developed based on our extensive filter engineering experience, and it is very effective in coagulation ...

Filter Element

Cleaning / Recycling

We offer the cleaning options most suitable for the elements and filters.As all of our cleaning equipment is located inside the filter element manufacturing plant, we can maintain a consistent quality control throughout the cleaning process until final inspection. This in-house facility also enables us to respond quickly to any emergency request. Cleaning process consists ...