PLANT TOUR

Plant Tour

PLANT TOUR

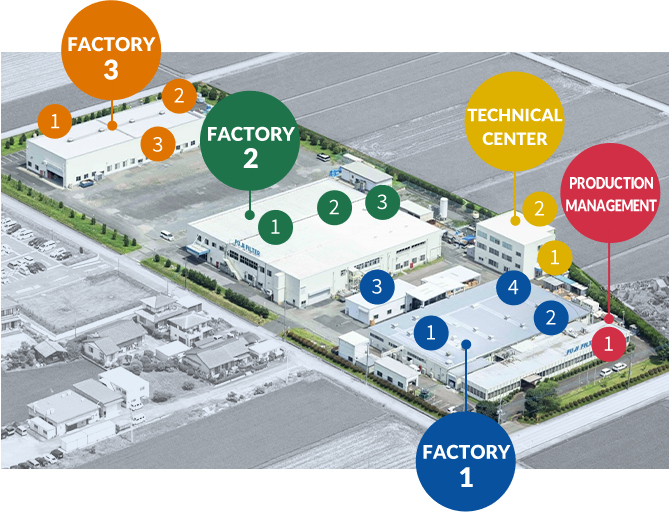

Fuji Filter Tochigi Plant

Factory 1

-

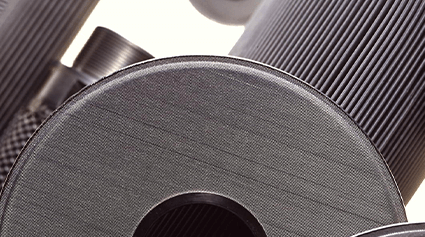

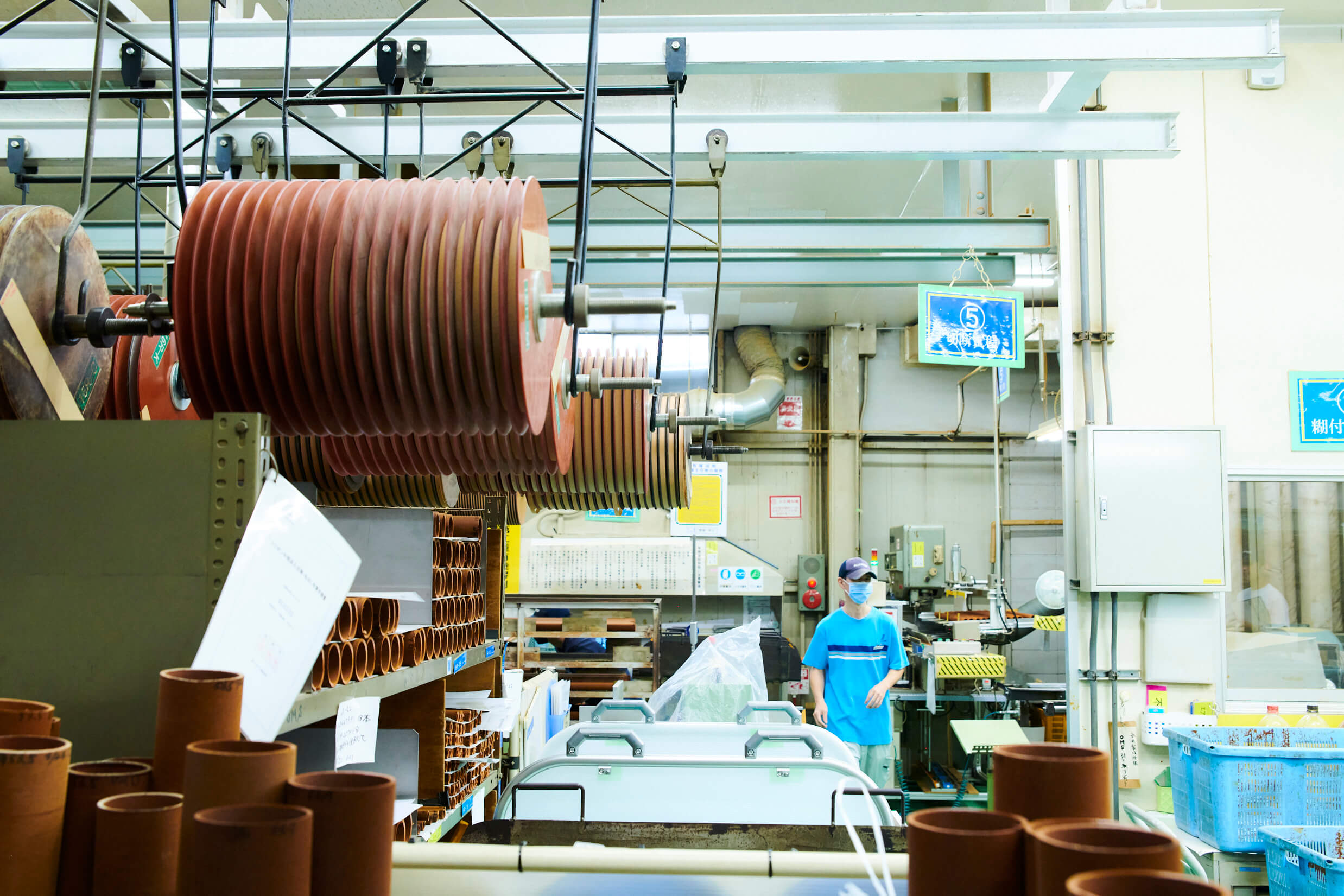

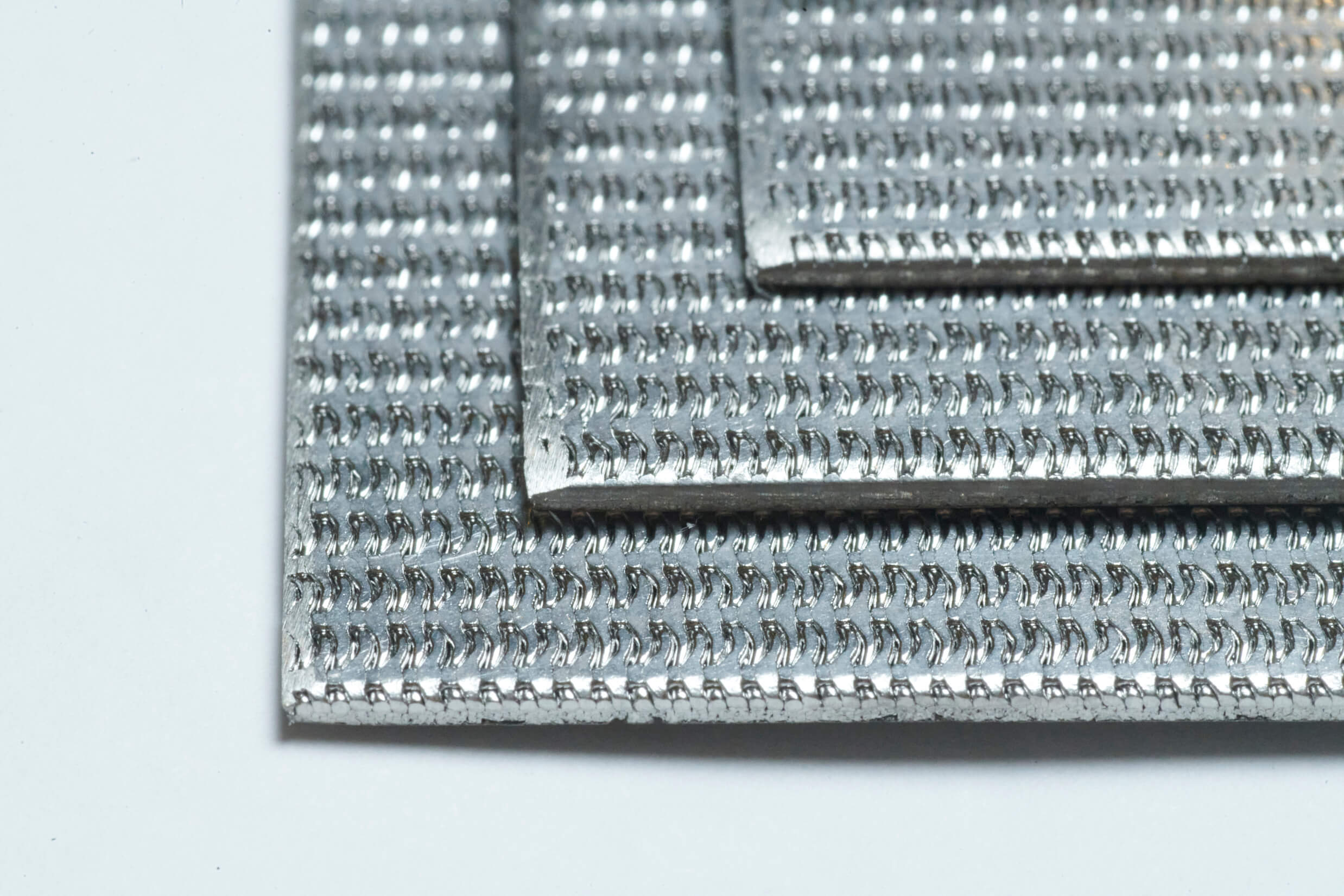

1 Processing of Metal Filters

-

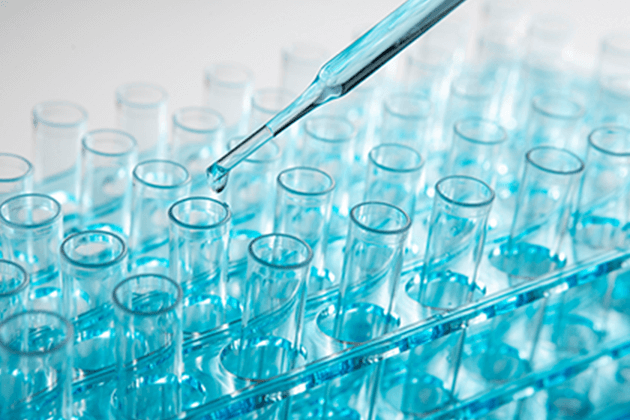

2 Production of Paper Filter

-

3 Procurement of Parts and Materials

-

4 Shipment

Factory 2

-

1 Mass Production System

-

2 Inspection, Measurement and Test

-

3 Shipment

Factory 3

-

1 Heat Treatment (Sintering)

-

2 Heat Treatment (Recycling)

-

3 Assembling

Technical Center

-

1 Trial Production and Experiment

-

2 Design Development

Production Management

-

1 Operation Management of the Plant